About Me

Hello, I'm V, a dedicated and passionate engineer specializing in embedded systems and product development. With over a decade of experience in software development, my primary focus has been on the intricate and fascinating world of embedded systems.

My journey in this field has been largely self-directed, driven by a curiosity and a desire to understand the technologies that are shaping our world. This self-guided exploration has heled me to acquire a diverse set of skills, including electronics, 3D printing, and model design.

In the realm of electronics, I've honed my abilities in areas such as circuit design, signal processing, and working with microcontrollers. I've also developed a strong foundation in 3D printing, gaining practical experience in creating rapid prototypes and iterating designs for optimal performance.

Model design has been another area of focus for me. I've utilized the V-Model in my work, a robust framework that emphasizes verification and validation at each stage of development. This approach ensures high-quality outcomes and aligns perfectly with my commitment to excellence.

Beyond these technical skills, I bring a problem-solving mindset and a knack for innovation to all my projects. I believe that continuous learning and adaptation are key to navigating the ever-evolving landscape of technology.

Whether I'm working on a complex embedded system or developing a new product, my goal remains the same: to create solutions that are not only effective and reliable, but also have a meaningful impact. I look forward to bringing my skills and passion to new challenges and opportunities.

Skills

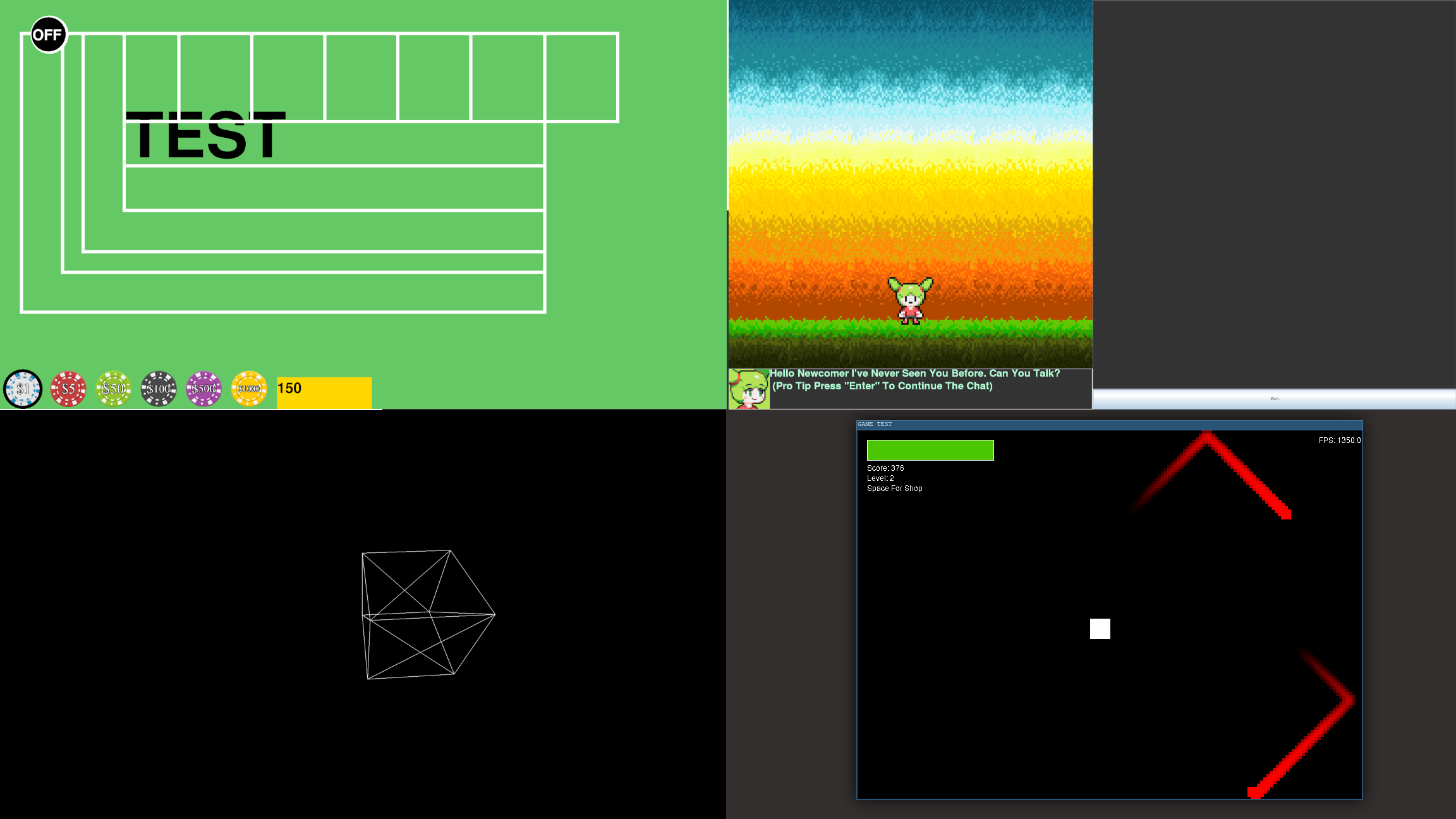

Programming Languages: Proficient in C/C++, Python, C#, Java, MicroPython, Assembly, and GLSL, I thrive on crafting efficient and robust code. My knowledge extends to Bash scripting, enabling powerful automation solutions.

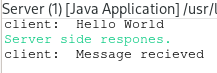

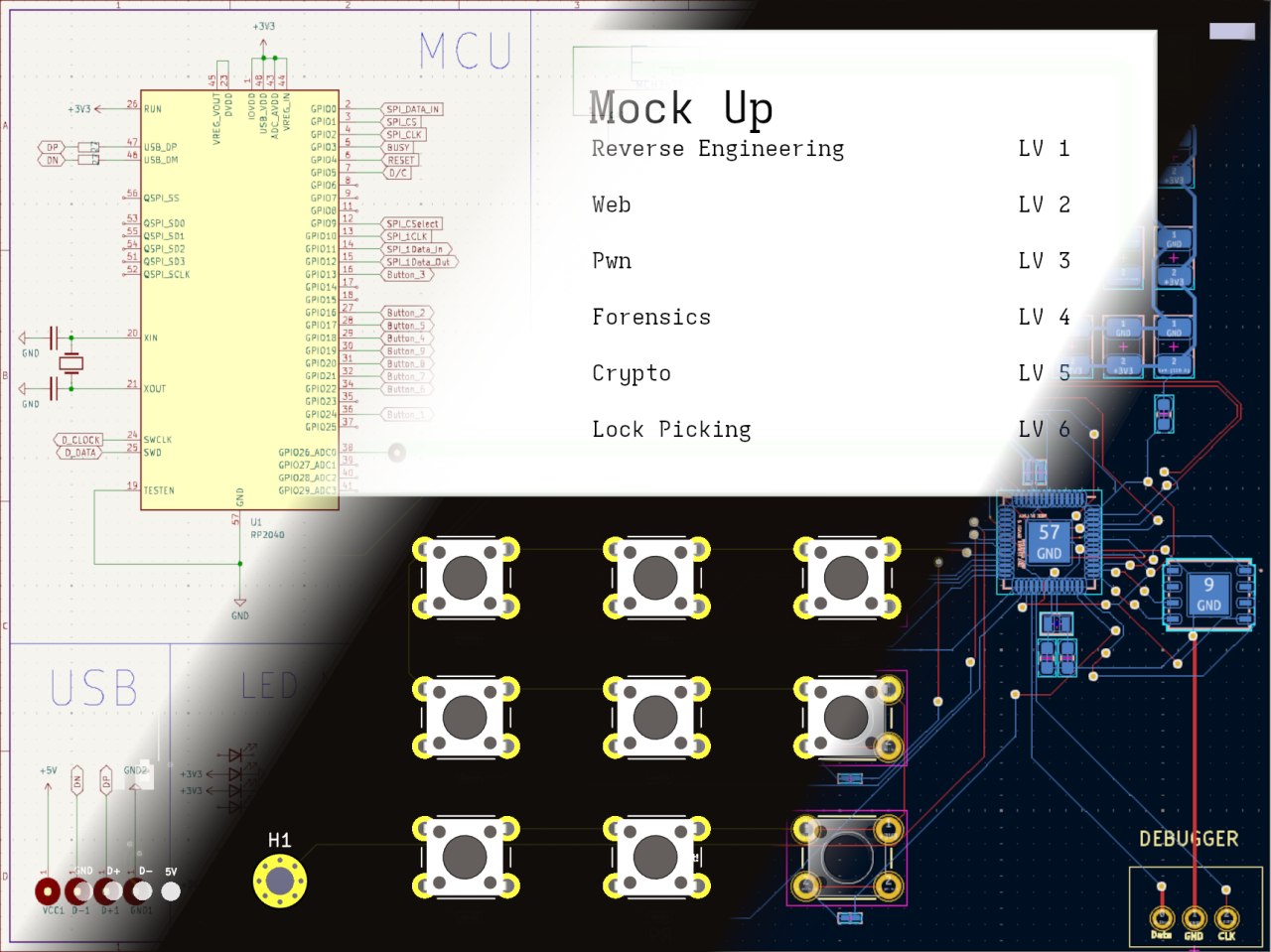

Technical Tools: I am adept with Linux/Unix systems and have hands-on experience with a variety of CAD tools including AutoCAD, LibreCAD, EagleCAD, and KiCAD. My proficiency also includes electrical simulation software like MULTISIM and a deep understanding of embedded systems with ecosystems like Arduino and QMK.

Version Control & Automation: I utilize git for seamless version control and Jenkins for continuous integration, ensuring high-quality and reliable development processes.

Design & Fabrication: My skill set covers comprehensive design and fabrication techniques, including 3D modeling and printing, as well as proficient soldering (both TMH and SMD). I leverage tools such as FreeCAD, LibreCAD, and much more, open source, tools for detailed and precise engineering designs.

Simulation & Testing: With experience in simulating both electrical and mechanical systems, I conduct thorough unit testing to validate designs. My capabilities in finite element analysis and truss engineering further enhance my analytical approach. As does my solid foundation of Control Engineering.

Certifications and Achievements

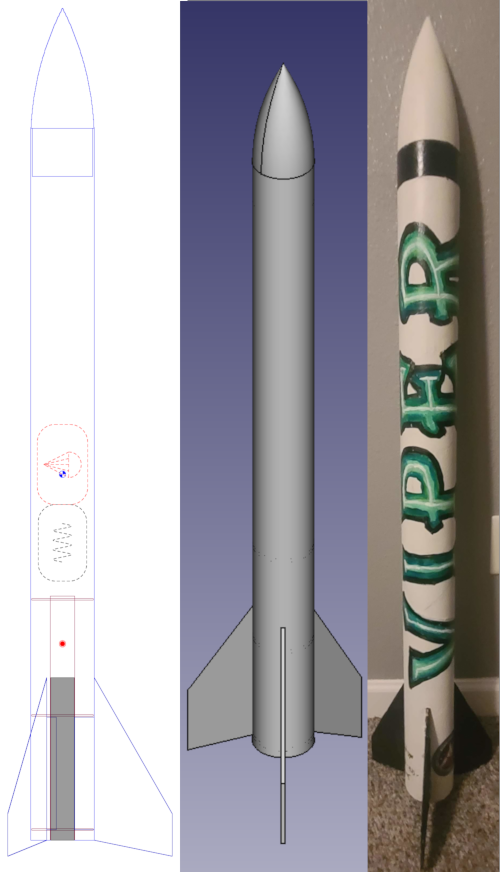

Level 1 Rocketry Certification: Earned my Level 1 Rocketry Certification, showcasing my ability to designing, building, and launching rockets safely, effectively, and budget friendly.

Technician Ham Radio License: Certified Ham Radio Technician, demonstrating my technical understanding in amateur radio operations and communication protocols.

National Cyber League Capture The Flag (CTF) Solo Score: Achieved a remarkable score in the National Cyber League Capture The Flag competition. View my Solo Score

National Cyber League Capture The Flag (CTF) Team Score: Contributed significantly to my team's success in the National Cyber League Capture The Flag competition. View my Team Score

Contact Me

Email: v@vsadygv.com